Lithium Niobate

(LiNbO3, LN)

Grinding

Devices that use lithium niobate

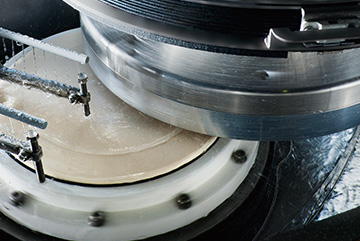

Lithium niobate grinding is used when processing lithium niobate wafers or other wafers that use lithium niobate. By using a high quality grinding process, the workload on the next polishing process can be reduced.

Because lithium niobate is mainly used for SAW filters in smartphones and telecommunication devices, they need to be ground to low thicknesses.

Features and things to consider when grinding lithium niobate

This section explains the special characteristics of grinding lithium niobate wafers.

Crack reduction

Because of its cleveage planes, there is a risk of cracking when grinding lithium niobate. The thermal expansion coefficient of lithium niobate greatly differs with crystallographic direction, which further adds to the risk of cracking. Grinding of lithium niobate is performed under the optimal grinding conditions and wheel that promotes self-grinding. Maintaining self grinding conditions when grinding lithium niobate reduces the risk of cracking.

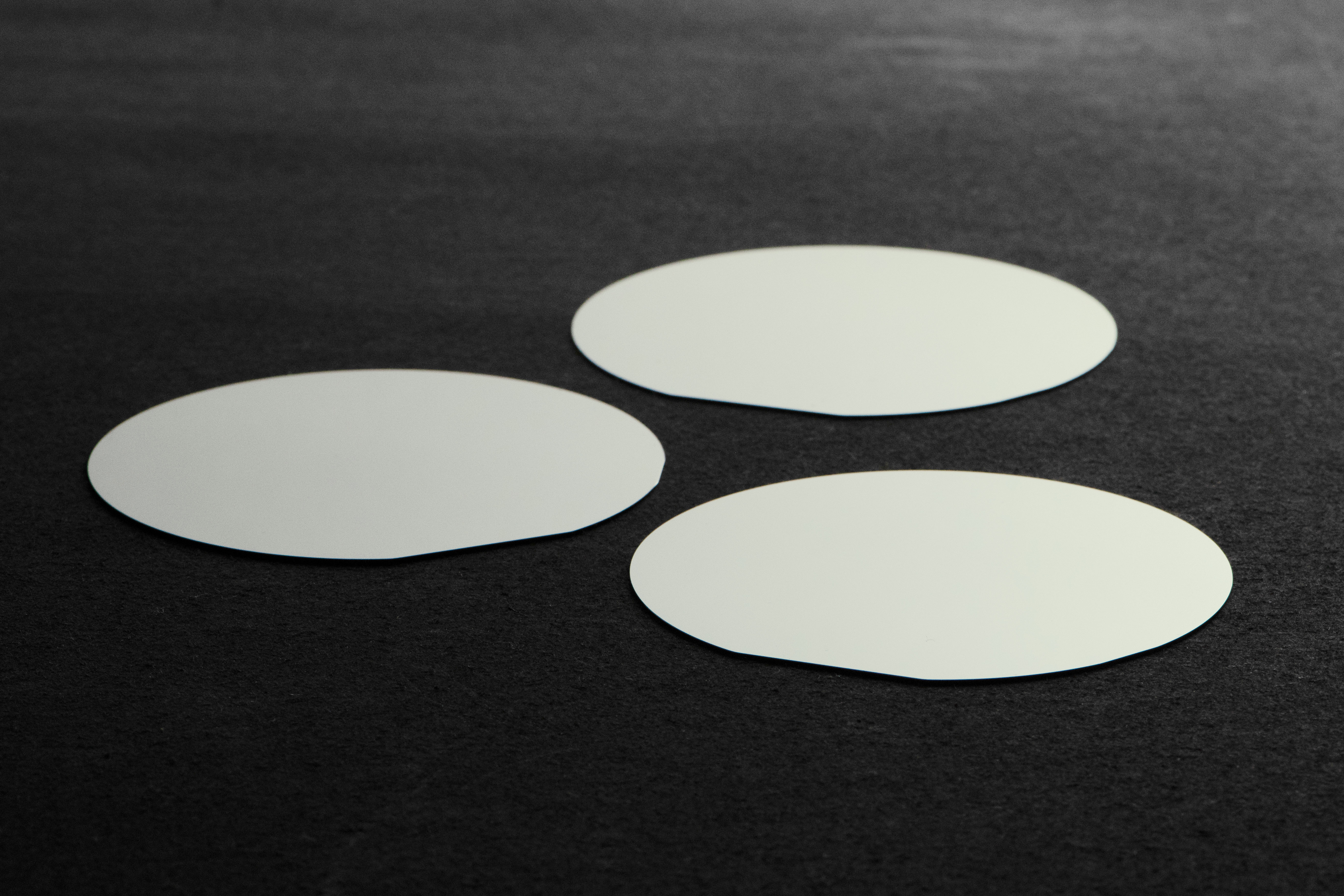

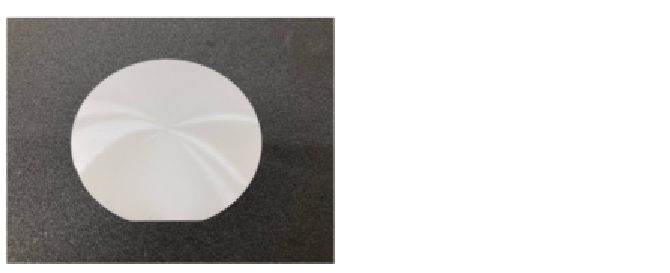

Process image

Below is an image of a lithium niobate wafer after whetstone grinding.

Wafer Diameter: Φ4in, Final thickness: 250µm

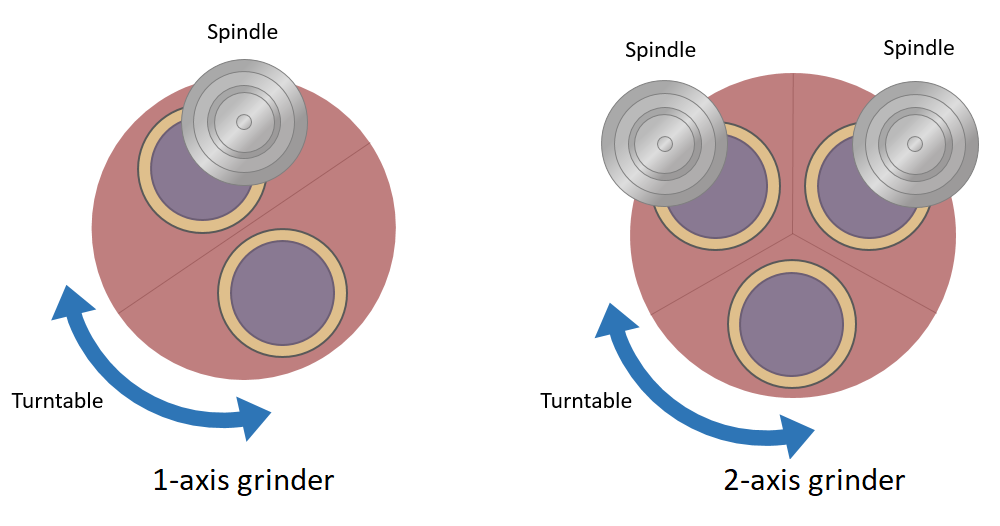

Machines used for processing

The machines used for grinding lithium niobate vary with the application. When grinding small amounts in high precision, single spindle grinders are used. In cases like manufacturing for SAW device substrates, where high throughput is necessary, dual spindle grinders are commonly used.

Related materials・processing methods

Machines used for high-precision machining

Tools used for high-precision machining

If you require solutions for your processing issues,

please contact DISCO CORPORATION.

-

Please contact DISCO CORPORATION.

Please feel free to contact us through the inquiry form or via phone call.

Inquiries -

Consultation for non-chargeable processing

If you are struggling with any processing issues,

please contact DISCO.Service details -

Easy confirmation in thirty seconds!

Online processing feasibility confirmationJust enter the conditions

Easy processing evaluation