Lithium Niobate (LiNbO3, LN)

- Elements

- Lithium (Li), Oxygen (O), Niobium (Nb)

- Substance Type

- Compund Material

Elements, Chemical Composition and Structure

Lithium Niobate(LiNbO3, LN) is a compound material consisting of the elements niobium (Nb), lithium (Li) and oxygen (O). It is also called lithium niobium oxide. It has a LN-type crystal structure, which is very similar to ilmenite structure of the trigonal system and thermally and chemically stable.

Lithium Tantalate (LiTaO3, LT) is also known to possess very similar structure and properties.

| Chemical Formula | LiNbO3 | LiTaO3 |

|---|---|---|

| Crystal Structure | Ilmenite-like Trigonal Crystal System | Ilmenite-like Trigonal Crystal System |

| Melting Point | ~1,250 ℃ | ~1,650 ℃ |

| Density | ~4.65 g/cm3 | ~7.45 g/cm3 |

| Mohs Hardness | 5 | 5.5 |

Properties

Lithium niobate displays piezoelectricity, pyroelectricity and nonlinear optical properties. They are used in piezoelectric and surface acoustic wave (SAW) devices. They are also used in laser devices for their nonlinear optical properties. It is possible to further enhance the pyroelectric properties and photorefractive damage resistance of lithium niobate by doping it with magnesium oxide (MgO). Lithium niobate that is doped by MgO is called black lithium niobate.

Production

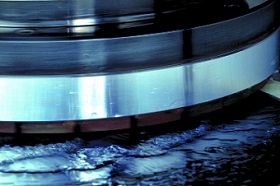

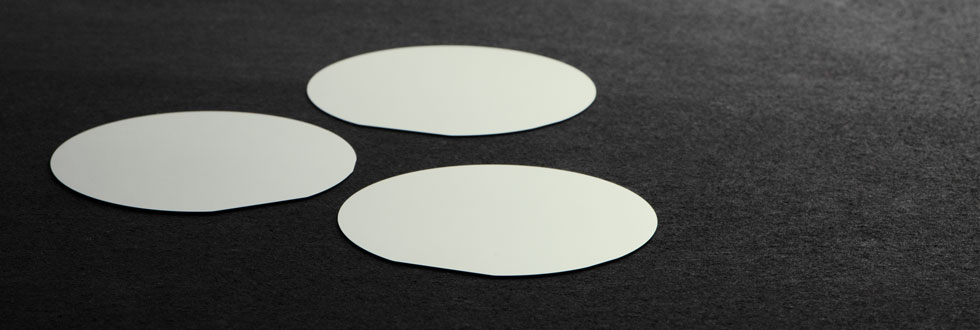

Lithium niobate can be grown using the Czochralski process. The ingot grown can then be sliced into thin wafers with a wire saw. Wafers of different properties can be obtained by changing the slicing angle and direction. The wafer is then processed into a substrate by either grinding, lapping or polishing.

DISCO's solution for LN substrate manufacturing

DISCO's grinders and polishers (Chemical-mechanical polishing machines, wet polishing machines) are used to process LN substrates.

Applications

Lithium niobate is the material of choice for surface acoustic wave (SAW) devices. It is widely used in SAW filters in telecommunication devices like smartphones. With the recent development of multi-band devices, multiple SAWs are needed to minimize radio wave noise and interference.

DISCO's processing solutions

DISCO's grinders, dicing and laser saws can be used for cutting and grinding lithium niobate substrate wafers.

Manufacturing method used to process this material

If you require solutions for your processing issues,

please contact DISCO CORPORATION.

-

Please contact DISCO CORPORATION.

Please feel free to contact us through the inquiry form or via phone call.

Inquiries -

Consultation for non-chargeable processing

If you are struggling with any processing issues,

please contact DISCO.Service details -

Easy confirmation in thirty seconds!

Online processing feasibility confirmationJust enter the conditions

Easy processing evaluation