Silicon (Si)

Dry Polishing

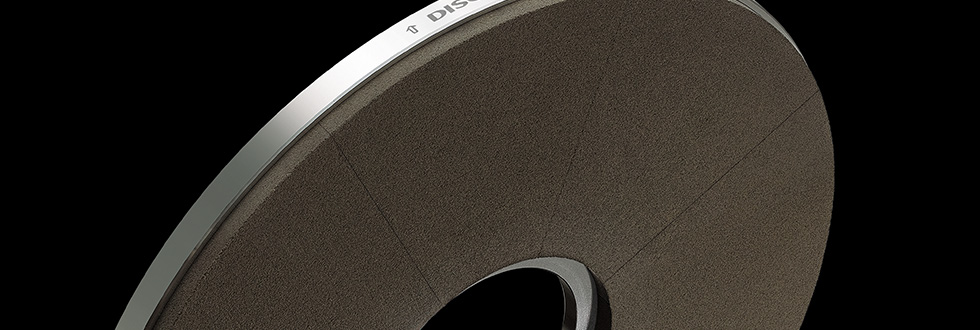

Polishing using a polishing wheel

Devices that use silicon

Dry polishing of silicon is widely used when manufacturing memory and microcontrollers for mobile devices, where the chips have to be very thin.

Features and things to consider when dry polishing silicon

This section explains the special characteristics of grinding and dry polishing silicon wafers.

Warpage reduction

In many cases, for silicon wafers ground to a thickness below 100μm, wafer warpage can be observed if only the back side of the wafer is ground. Dry polishing the surface after grinding can reduce warpage.

After grinding

Size: Φ8in

Thickness: 50 µm

Grinding wheel: #2000

Eliminating grinding damage

When looked under a TEM microscope, some damages on the back surface of a silicon wafer can be seen after grinding with a #2000 grinding wheel. After polishing about 1~2 μm with a dry polishing wheel and looked under the microscope again, it is observed that the damage has been eliminated.Die strength improvement

Ball-on-ring test is an easy method to assess the effects of processing onto the back side of the chip. When the strengths of a wafer that has only its back surface ground and a wafer that is both ground and dry-polished are compared by ball-on-ring test, the wafer that is ground and polished is shown to have higher die strength. This improvement in die strength is attributed to the elimination of grinding damage during polishing.

Process image

Below is an image of a silicon wafer after dry polishing.

Wafer diameter: Φ300 mm, Final thickness: 50 µm

Related materials・processing methods

Machines used for high-precision machining

Tools used for high-precision machining

If you require solutions for your processing issues,

please contact DISCO CORPORATION.

-

Please contact DISCO CORPORATION.

Please feel free to contact us through the inquiry form or via phone call.

Inquiries -

Consultation for non-chargeable processing

If you are struggling with any processing issues,

please contact DISCO.Service details -

Easy confirmation in thirty seconds!

Online processing feasibility confirmationJust enter the conditions

Easy processing evaluation