Surface planarization using bit grinding

Process Overview

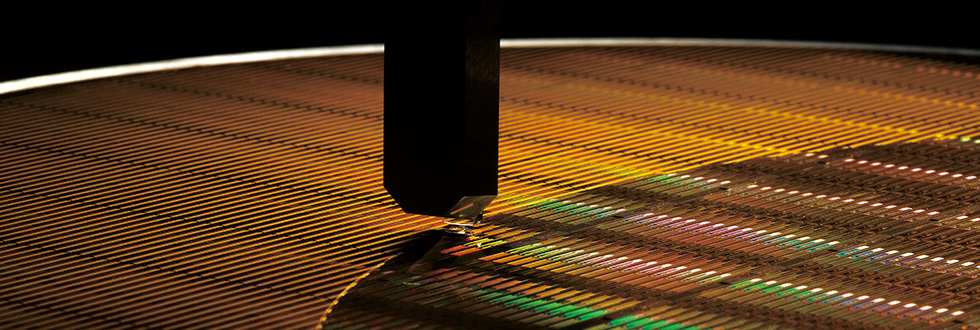

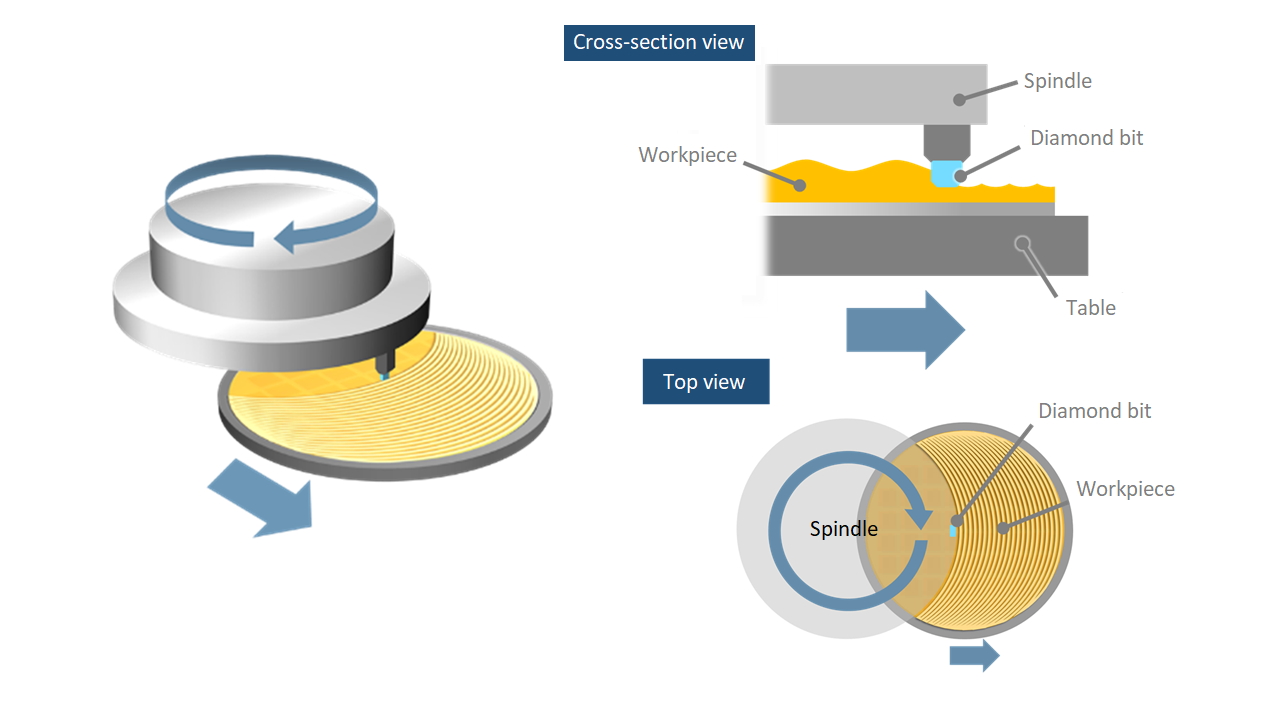

Surface planarization using bit grinding is the manufacturing process of removing surface topologies of a wafer using a cutting tool with a bit to achieve the desired workpiece thickness or surface roughness.

The cutting bit is placed vertically to the surface and eccentric to the center of the workpiece and rotated at a high speed. The height of the bit is set to a predetermined value; doing so will process the workpiece to the desired thickness. With this method, the surface of a workpiece that is a few millimeters thick can be flattened and trimmed from a few micrometers to several tens of micrometers.

Because the cutting tool should be more than 3 times harder than a regular cutting tool, a diamond bit is used in surface planarization.

During cutting, water (or pure water) is used for cooling and washing away the cutting debris.

Machines used for high-precision machining

Fully-automatic surface planer

A cassette of workpieces is loaded on the machine. The machine automatically loads, processes and cleans the workpiece and returns it to the cassette automatically.

Semi-automatic surface planer

Loading and cleaning of the workpiece is performed by a human operator.

Tools used for high-precision machining

Diamond bit

Target materials of bit grinding planarization

・Ductile materials(gold, copper, solder, etc.)

・Resin(photoresists, polyimide)

・Resin-metal compounds

・Tape substrates

If you require solutions for your processing issues,

please contact DISCO CORPORATION.

-

Please contact DISCO CORPORATION.

Please feel free to contact us through the inquiry form or via phone call.

Inquiries -

Consultation for non-chargeable processing

If you are struggling with any processing issues,

please contact DISCO.Service details -

Easy confirmation in thirty seconds!

Online processing feasibility confirmationJust enter the conditions

Easy processing evaluation