Dry Polishing

Polishing using a polishing pad

Process Overview

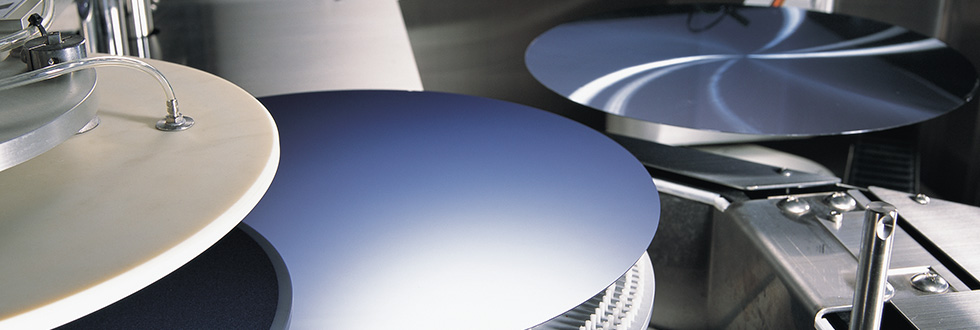

Dry polishing is the polishing process that does not involve water or any other chemicals or slurries containing abrasive particles. Polishing processes that involves water or chemicals are called wet polishing. In dry polishing, flat objects with a thickness of several millimeters or less are polished with a dry polishing wheel (polishing pad) to achieve a mirror finish surface.

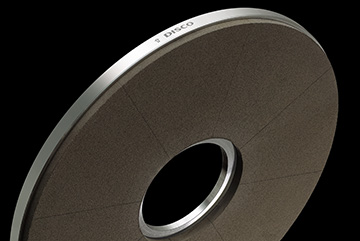

The dry polishing wheel is a circular pad with abrasives attached to a base and it does not require water or chemicals during processing. Different types of polishing wheels exist for different types of materials.

For the process, the dry polishing wheel is installed on the processing axis so that it is parallel to the table. During the process, both the wheel and the table are rotated, and the wheel is pressed uniformly onto the wafer. This way, the whole surface of the wafer is polished.

Since dry polishing, contrary to wet polishing, does not use any water or chemicals during processing, it does not require a recirculation or disposal system, making it an environmentally friendly processing method.

Small damages are often observed on the back side of semiconductor wafers when processing them to thicknesses below 100μm. To minimize this, a process called stress relief is used. Dry polishing is used when stress-relief processing silicon wafers.

achines used for high-precision processing

DISCO has fully automatic machines that have only has polishing functions, as well as a machines with both grinding and polishing functions.

For the polishing process, a wafer is placed between the table and the dry polishing wheel, with the table at the bottom and the wheel on top.

-

Fully Automatic

PolisherPad polishing

-

Fully Automatic Grinder-Polisher

Whetstone grinding, pad polishing

Fully Automatic Polisher

In addition to the polishing section, these machines have transferring and washing capabilities and can process a whole cassette automatically.

Fully Automatic Grinder-Polisher

With both grinding and polishing combined in a single machine, the fully automatic grinder-polisher is also equipped with transfer and washing capabilities and thickness measurement of thin wafers.

Tools used for high-precision processing

Main target materials processed with dry polishing

・Back surface mirror finish polishing of semiconductor wafers (silicon, SiC)

・Back surface mirror finish polishing of optical device parts (sapphire)

Material processing using dry polishing

If you require solutions for your processing issues,

please contact DISCO CORPORATION.

-

Please contact DISCO CORPORATION.

Please feel free to contact us through the inquiry form or via phone call.

Inquiries -

Consultation for non-chargeable processing

If you are struggling with any processing issues,

please contact DISCO.Service details -

Easy confirmation in thirty seconds!

Online processing feasibility confirmationJust enter the conditions

Easy processing evaluation